Kinetics Neo

How fast are your chemical reactions?

News

Sticky. Article "ICTAC Kinetics Committee recommendations for analysis of multi-step kinetics" is published (free download link).

January 29, 2024 New Kinetics Neo version 2.7.0 is released. Main new feature is adding of diffusion control to simulation of curing reactions in Viscosity and DEA projects. Details are in Release History.

November 21, 2023. Webinar Termica Neo: The New NETZSCH Software for Thermal Simulation on an Industrial Scale

Dr. Elena Moukhina showed new NETZSCH Termica Neo software for simulation of industrial processes such as curing or polymer crystallization where the temperature gradients in the reacting media have an influence on product quality, as well as for highly exothermal materials where temperature gradients impacts the safety conditions of runaway reactions. Termica Neo uses all kinetic methods recommended by ICTAC, is fully compatible with the NETZSCH Kinetics Neo software, and works for both model-free and model-based approaches, as well as for complex reactions. The simulation examples for curing, material storage, and simulation in liquids with and without stirring were shown.

Video: Filecloud

PDF: download

November 06, 2023. Because of many customer questions about the realization of Kamal-Sourour model, a new F.A.Q article is added "How Kamal-Sourour parameters in Kinetics Neo correspond to original equation da/dt=(k1+k2*a^m)*(1-a)^n?".

September, 18-21, 2023. NETZSCH will have two presentations on Heat Flow Calorimetry Symposium Energetic Materials (HFCS-EM), The Hague in The Netherlands: New NETZSCH software for simulation of reactions in big volumes and Simulation of material storage by NETZSCH Termica Neo software.

September 13, 2023. New Kinetics Neo version 2.6.8 is released. This version is a minor release with several improvements and bug fixes. Details are in Release History.

Kinetics Neo Roadmap

The actual Kinetics Neo version 2.7.0 was released on January 29, 2024.

Check our release history for more information.

Future Releases

Q3 2024

What Is Kinetics Neo Software

The kinetics, also called reaction kinetics or chemical kinetics, investigates the rates of chemical processesand allows for the determination of reaction rates. It also takes the factors that control these rates into consideration. Knowledge about points such as these can give deep insight into the detailed molecular mechanisms behind elementary reactions.

NETZSCH Kinetics Neo software is used to analyze chemical processes. The software allows for the analysis of temperature-dependent processes. The result of such analysis is a kinetics model or method correctly describing experimental data under different temperature conditions. Use of the model allows for predictions of a chemical system’s behavior under user-defined temperature conditions. Alternatively, such models can be used for process optimization.

The software can analyze different types of thermal curves that depict the changes in a given material property measured during a process. Potential data sources include studies using Differential Scanning Calorimetry (DSC), Thermogravimetry (TGA), Dilatometry (DIL), Dielectric Analysis (DEA), Accelerating Rate Calorimetry (ARC), Rheology and Viscosity (Torque).

Please have a look at the video about the basics of the Kinetics Neo and it's advanced functions and features recorded during the webinar at April 29, 2021. Important parts are:

- 02:25 Target of thermokinetic analysis and necessary measurements (slides 3-9, 8 minutes);

- 10:38 Analysis approaches, advantages and disadvantages (slides 10-24, 17 minutes);

- 27:54 Unique features of Kinetics Neo (slides 27-48, 23 minutes).

Kinetics Neo Can Help If You Need To:

- Determine the amount of time needed for paint to cure;

- Optimize production time for qualitative ceramics;

- Maximize the quality of metal powder product during polymer burnout;

- Check how quickly a pharmaceutical is able to work;

- Optimize a material’s synthesis process when using a new catalyst;

- Find out the curing time for a dental filling.

Supported Measurement Types

- Differential Scanning Calorimetry (DSC) / Differential Thermal Analysis (DTA),

- DSC with Diffusion Control,

- Thermogravimetric Analysis (TGA) / Thermogravimetry (TG),

- Dilatometry (DIL),

- Dielectric Analysis (DEA),

- Accelerating Rate Calorimetry (ARC),

- Rheology,

- Viscosity (Torque).

What Makes Kinetics Neo So Valuable:

- Completely rewritten from scratch, this innovative software is based on the latest technologies.

- The improved user interface is fast and easy to use.

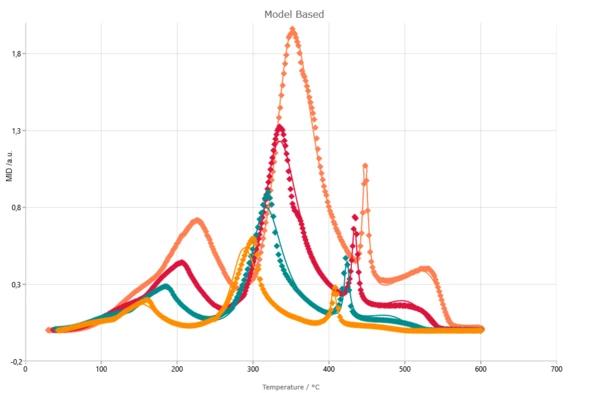

- All model-free and model-based methods are included. The results from all of these methods can be statistically compared wit h one another.

- The powerful new numerical model-free method ensures fast determination of the best model-free solution.

- Predictions and optimizations can be achieved by means of both model-free and model-based methods.

- A visual kinetic model can be created quickly and easily using the model-based method.

- The kinetic model can contain any number of individual reaction steps in any combination. Reaction steps can be easily added, removed or changed by the user.

- The position of individual reaction steps can be visually adjusted at any time.

- An individual step or the entire kinetic model can be optimized with just a click of the mouse.

- The software provides the formal concentration of each reactant and reaction rate for each reaction step as a function of time or temperature.

- Isothermal crystallization reactions can be analyzed and predicted.

Kinetics Neo Features

Kinetics Neo follows the latest ICTAC recommendations published in the article "ICTAC Kinetics Committee recommendations for analysis of multi-step kinetics".

Model-Free Methods allow the activation energy of the reaction process to be found without the assumption of any kinetic model (ASTM E698, ASTM E2890, ASTM E1641, Friedman, Ozawa-Flynn-Wall, KAS, Numeric Optimization).

Model-Based Methodsapply powerful cutting-edge mathematical calculations to create the best kinetic model; the different kinetic models can then also be compared statistically.

Predictions— Kinetics Neo is used for simulations and predictions once the experimental data has been described by either model-free or model-based kinetics. Predictions can be calculated for various temperature programs: isothermal, dynamic, multiple step, step-iso, modulated, or adiabatic.

Optimization is based on predictions; the temperature program can be optimized to achieve maximum product quality in the minimum amount of time.

System Requirements

Kinetics Neo runs under Microsoft Windows 11 64-bit or Windows 10 64-bit version. Microsoft .NET Framework version 4.8 is required.

Minimum hardware requirements are: Intel i5 or similar CPU, 8 GB RAM. Faster processor (more MHz) and bigger RAM increase calculation speed.