How To: Analyze Cooling Crystallization of PBT (Polybutylene Terephthalate)

by Crystallization According to NakamuraCrystallization according to Nakamura is the crystal growth model for non-isothermal crystallization kinetics during cooling.Nakamura Method Using Hoffman-Lauritzen Theory

Compatibility

This guide can be used for Kinetics Neo version 2.1 or later.

Introduction

Crystallization of polymers depends on the two parameters: conversion alpha and temperature T: d(alpha)/dt=f(alpha)*K(T).

Here the part f(alpha) which depends on conversion, has Avrami nucleation type, and the part K(T) is the Nakamura expression with Hoffmann-Lauritzen theory.

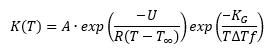

For the analytical dependence K(T) the Hoffman-Lauritzen theory can be used:

Where:

- A - the pre-exponential factor;

- U – activation energy of segmental jump in polymers, this parameter has universal value 6.3kJ/mol;

- T∞ =Tg-30 - temperature at which crystallization transport is finished, this temperature is 30K below the glass transition temperature Tg;

- KG – kinetic parameter for nucleation;

- ∆T=Tm-T - undercooling from the equilibrium melting point Tm;

- f=2T/(Tm+T) – correction factor.

In this "How To:" two kinetic models for crystallization of PBT during cooling will be created. The first model contains primary crystallization only, the second model contains both primary and secondary crystallization. For both crystallization types Nakamura method is used.

We will start by loading an experimental data included in Kinetics Neo, and then create models by Nakamura method.

Sample data:

Data Type: DSC (Differential Scanning Calorimetry),

Project Data: are located in directory <Samples>\DSC_PBT_Crystallization.

Load the Sample Data Project

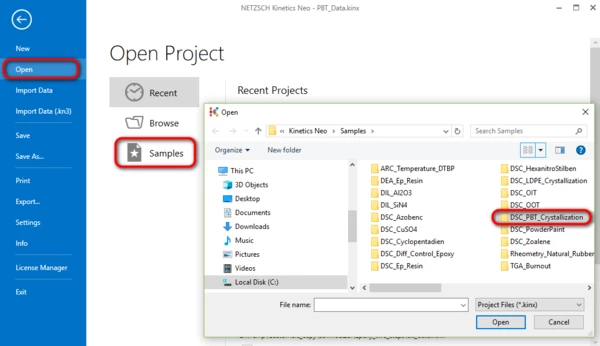

1. Start the Kinetics Neo software. Click on the blue "File" tab to open the application menu.

2. Open the Sample Data DSC project. Click on "Open" in the menu on the left side, then select "Samples". The Kinetics Neo samples directory will be opened in Windows Explorer.

Select the directory “DSC_PBT_Crystallization”.

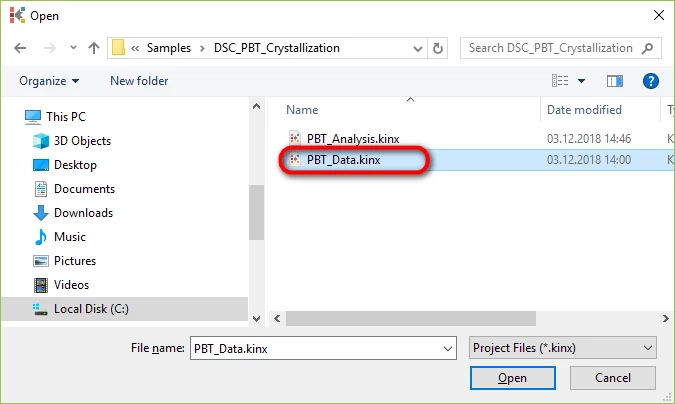

3. Open the Kinetics Neo project file “PBT_Data.kinx”

Check The Loaded Measurement Data

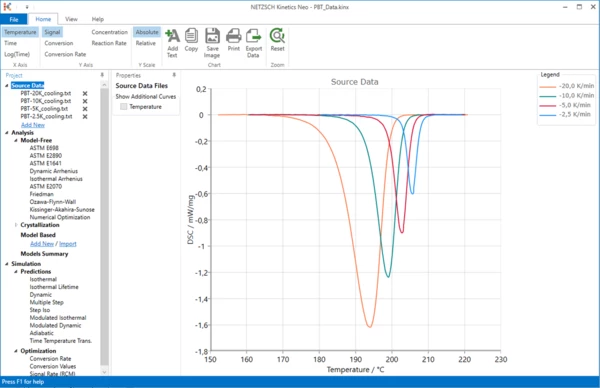

4. Check whether the DSC measurement data are loaded.

The Kinetics Neo sample project "PBT_Data.kinx" already contains imported sample DSC measurement data files for crystallization during cooling:

- PBT-2.5K_cooling.txt- cooling rate 2.5 K/min;

- PBT-5K_cooling.txt- cooling rate 5 K/min;

- PBT-10K_cooling.txt- cooling rate 10 K/min;

- PBT-20K_cooling.txt- cooling rate 20 K/min;

If the project file is successfully loaded then these file names will be seen in the "Source Data" section on the left side. The data curves will be shown on the main chart.

Check Baseline Type

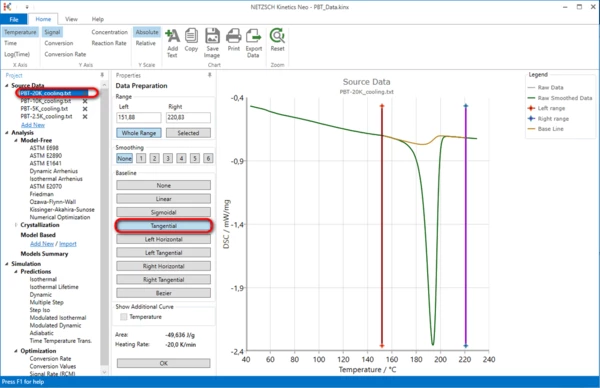

5. Check baseline type for the first DSC measurement.

In the left Project panel select measurement PBT-20_cooling.txt in order to check, that tangential baseline is used:

6. Check baseline type for all other DSC measurements. The tangential baseline should be selected.

Create One-Step Kinetic Model (Nakamura Method) For The Primary Crystallization

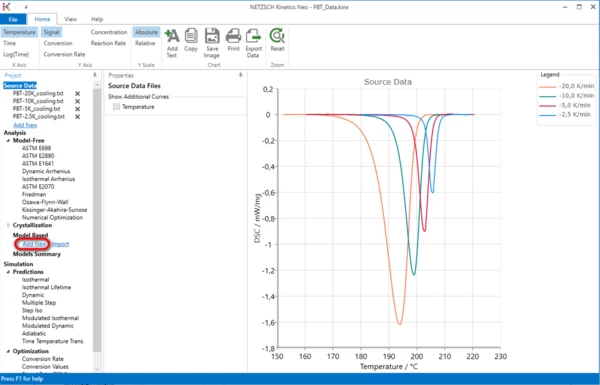

7. Add new model: In "Analysis" tree under "Model Based" click on "Add New":

A new "Model Based" kinetic model will be created with default parameters:

- One step: A -> B;

- Optimizate Fit To: Signal;

- Reaction type: F1, 1st order reaction.

The first model step A -> B will be selected.

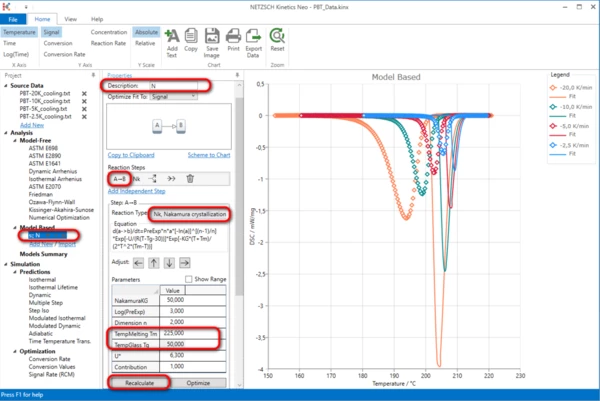

8. Let's select Nakamura model and change some parameters of it .

- First of all, change field “Description” to “N” for Nakamura model.

- In the Reaction Type drop menu change the reaction type from the default value "F1, 1st order" to "Nk, Nakamura crystallization".

- Set parameter “TempMelting Tm” of melting temperature to 225°C. This is the value near equilibrium melting temperature for PBT. This parameter will be optimized during the fitting of model.

- Set parameter “TempGlass Tg” of glass transition temperature to 50°C. This parameter will not be changed during the fitting of model.

- Press “Recalculate” in order to see the simulated result for these parameters.

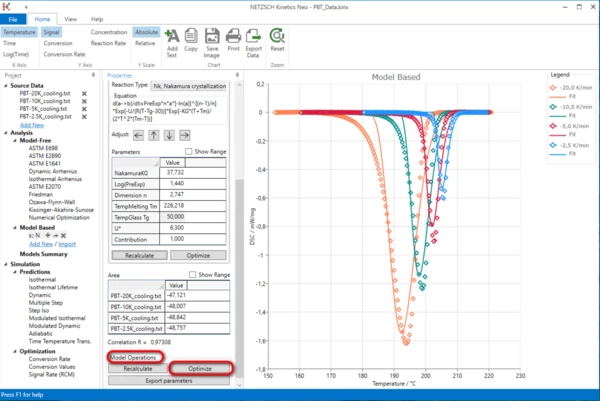

9. Optimize Nakamura parameters.

In the lowest section “Model Operations” click “Optimize” in order find Nakamura parameters for the best fit.

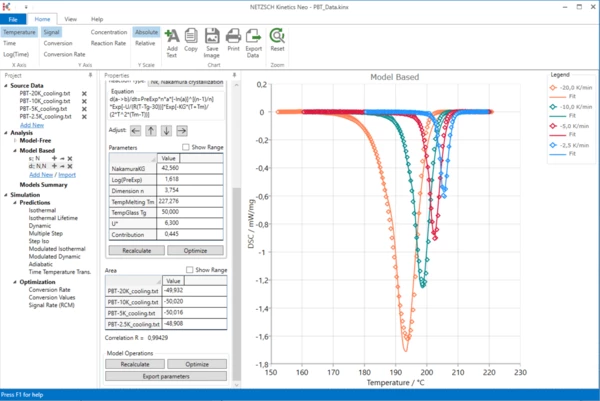

Now the model for the primary crystallization is created. The end of crystallization (near 180°C for 20K/min cooling) has not the good fit because the secondary crystallization is present in experiment, but not present in the model.

Create Two-Step Kinetic Model (Nakamura Method) For The Primary And Secondary Crystallization

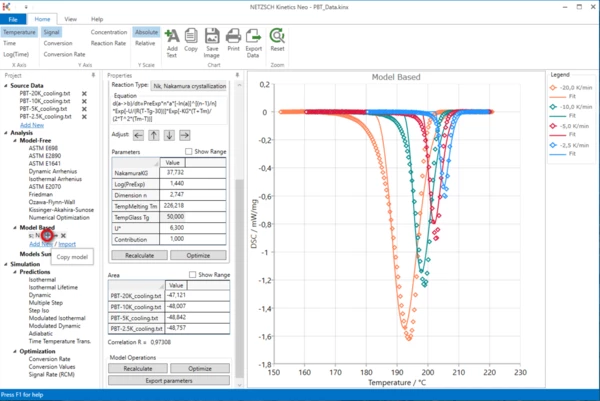

10. Create the copy of the single-step Nakamura model.

Click on “+” in the model line in the tree panel.

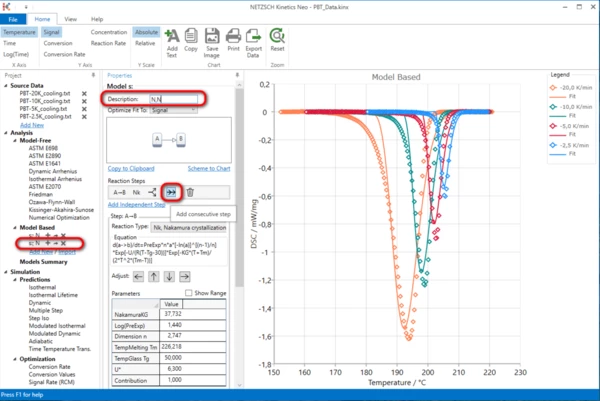

11. Add the new crystallization step for the secondary crystallization.

- Set Description for double-step crystallization to”N,N”

- Add the new consecutive step to the step “A->B”

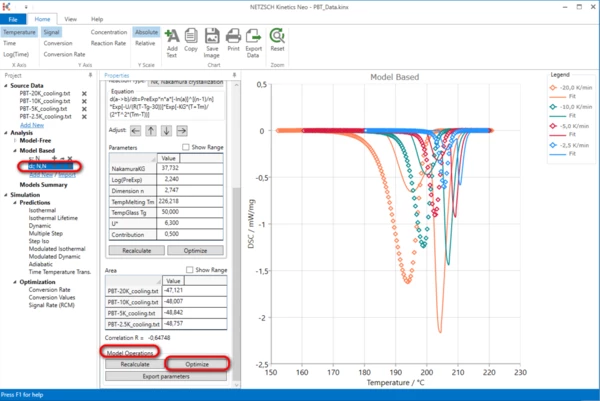

12. Optimize Nakamura parameters for both primary and secondary crystallization.

In the lowest section “Model Operations” click “Optimize” in order find Nakamura parameters for the best fit.

Now the simulated data are in good agreement with the experiment at the end of crystallization: near 180°C for 20K/min cooling.

Result:

Compare Single-Step And Double-Step Models

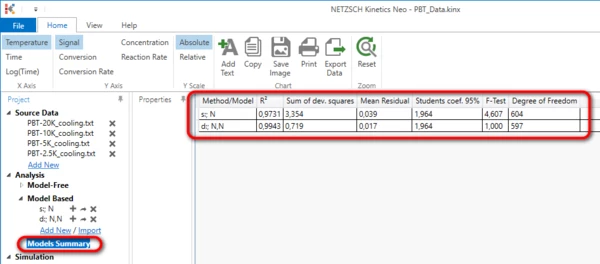

13. Compare models.

Now you can compare single-step model with primary crystallization and double-step model having both primary and secondary crystallization.

Select “Model Summary” in the tree panel. Here the statistics for both models is present.

Double-step model better fit the measurement because it has higher R-square, lower sum of deviations of squares and mean residual.

Conclusion

The crystallization of PBT can be described as a double-step crystallization by Nakamura reaction type.