Reduce the Costs of Ceramic Production with Kinetics Neo

NETZSCH Business Field Manager, Dr. Elena Moukhina explains how the Kinetics Neo software helps perform polymer debinding and ceramic sintering processes more quickly and efficiently.

Introduction

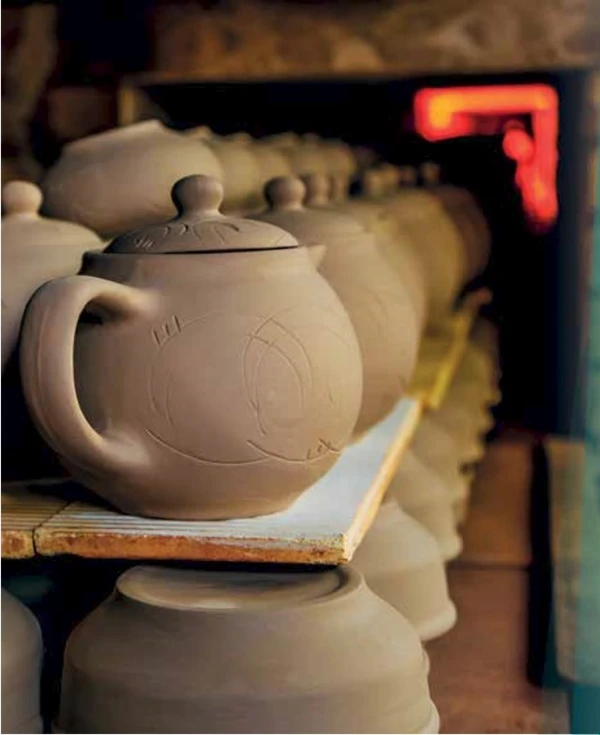

Ceramic production is a challenge in the world of high energy prices.

How to reduce the costs of ceramic firing and keep the high quality of the product?

If a part leaves the kiln with cracks and deformations, most process engineers will lower the heating rates and make isothermals longer. This ends up in very long debinding and sintering processes and increase the costs dramatically.

If parts leave the furnace in a good quality, no one will touch the process anymore to find our if it is possible to get the same result in 50% of the time.

But now we have to do this, because the energy prices are too high.

The software NETZSCH Kinetics Neo and the data from thermal analysis support you with a virtual view in into your process inside the kiln. It helps you to design your process to the best by:

- reducing R&D time

- reducing energy consumption

- reducing the numbers of test-fires

- reducing scrap

- keeping the same or getting the better quality

- speeding-up your time to market

See how it works: https://vimeo.com/268580866

Why the Temperature Optimization of Ceramic Firing is Necessary?

In ceramic firing, the quality of the product depends on the temperature profile, particularly the heating rate. In the initial stage of the heating process, usually below 700°C, the polymer binder is carefully removed via thermal decomposition. But the evolving of gas should not be too intensive to prevent the formation of micro-cracks and ensure the structure of the original material is not destroyed. Therefore, in order to obtain the best product quality, this heating stage to achieve polymer decomposition should not be performed too quickly. On the other hand, heating that is excessively slow increases the process time, which could be overly expensive and ecologically unfriendly as well as increasing production costs.

In the final stage of the heating process, usually above 700°C, the sinter process with the shrinkage takes place. The too intensive heating leads to the formation of mechanical stresses and micro-cracks. Thus, in order to obtain the best quality of ceramics, this heating stage with shrinkage should not be performed too quickly. However, too slow heating increases the process time, and corresponding production costs.

The main objective is to create an optimal temperature profile having balanced heating to ensure the best quality material in the shortest time.

The process-engineer can use "trial & error" to find suitable firing programs. He tries to do justice to each individual process during the sintering process. This leads to long firing programs that do not optimally match the real course of the sintering process.

What Can I Do to Find the Optimum Temperature for my Production Process?

At first, it makes sense to look at the dehydration and debindering by Thermogravimetry. With this method the experimental data present the temperatures, where the specimen lose weight - which tells us: "Something comes out of the material". If you no longer see mass losses, you can assume, that debindering is completed.

In a second step, the material must be characterized with the help of Dilatometry. This measurement method shows, where sintering starts and at which temperatures sintering steps occur. Finally, if you no longer see shrinkage, sintering is completed. Running both tests under different heating rates, it tells you, how the processes are dependent on speed.

For the optimization of the firing profile, the Kinetics Neo software can be used. It can analyze the data from thermogravimetry and dilatometry, and then simulate the debinding any sintering for any temperature profile.

Optimization steps

- Thermogravimetric measurements with different heating rates below 700°C for debinding

- Kinetic analysis of thermogravimetric measurements and creating of kinetic model for debinding

- Optimization of temperature profile below 700°C in order to have mass loss rate, which is close to constant value.

- Dilatometer measurements with different heating rates above 700°C for sintering

- Kinetic analysis of dilatometer measurements and creating of kinetic model for sintering

- Optimization of temperature profile above 700°C in order to have shrinkage rate, which is close to constant value.

- Validate the complete temperature profile, firstly in laboratory and then in industrial conditions

Kinetics Neo: Kinetic Analysis

If the data, which were measured under different heating rates, loaded into the simulation software Kinetics Neo, then the reaction kinetics can be mathematically modeled. What you get is a simulation model that reliably describes the temperature-dependent and time-dependent processes in your material.

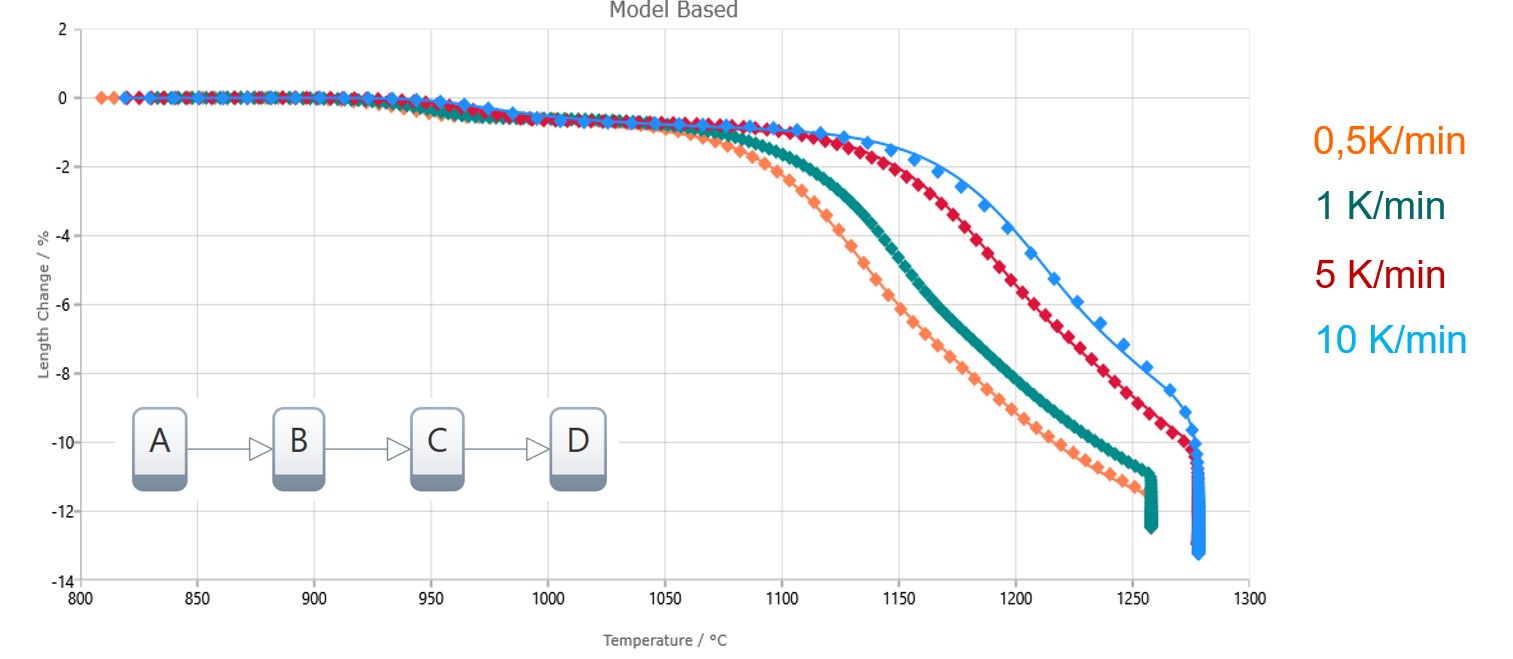

Fig. 1: Sintering Curves and model fit in Kinetics Neo for constant heating rates

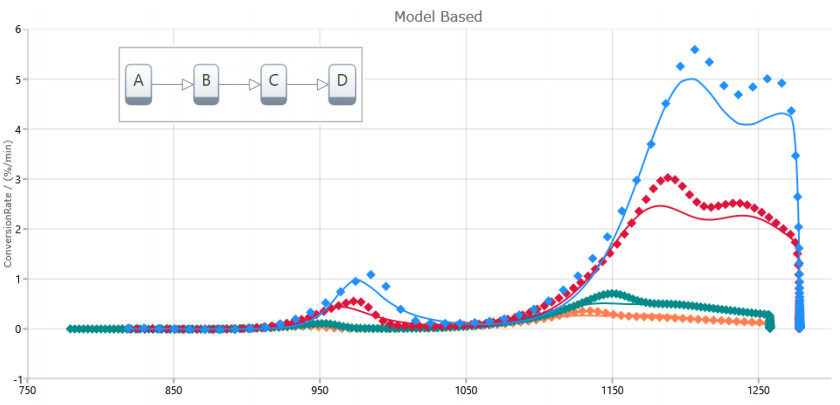

The Figure 1 shows the dilatometer-curves and the fit calculation from the three-step kinetic model. The Figure 2 contains the same data and model for the conversion rate. The peaks on these curves presents the critical points with intensive shrinkage, where mini-cracks can occur.

Fig. 2: Conversion rates in %/min - this shows you areas, where sintering is very intensive and therefore here the cracks or deformation can occur.

Kinetics Neo: Simulation and Optimization

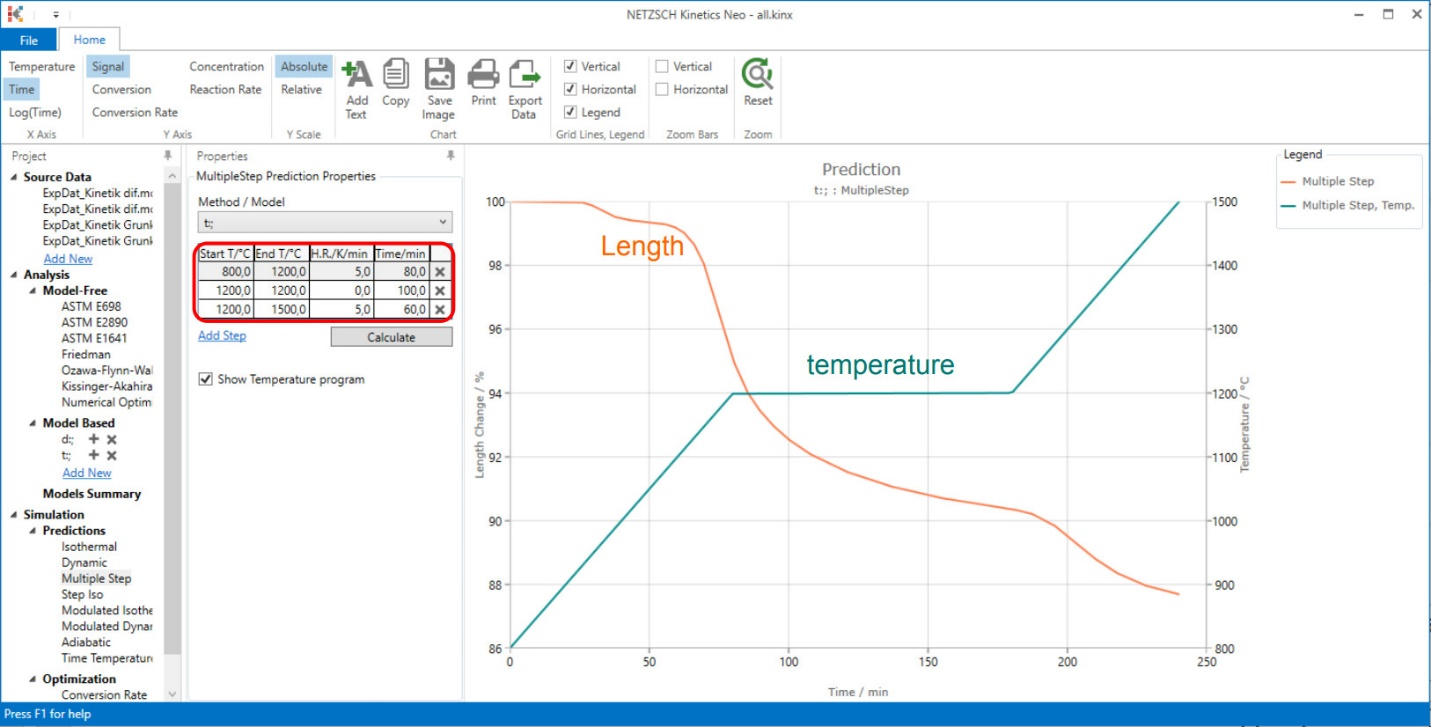

The simulation of the sintering process for the temperature profile with three segments (heating, isothermal, heating) is present in the Figure 3.

With this model you can now simulate any burning program and the effect on your sintering process just by changing temperature in the software.

Fig. 3: Simulation of a sintering curve with a given firing program

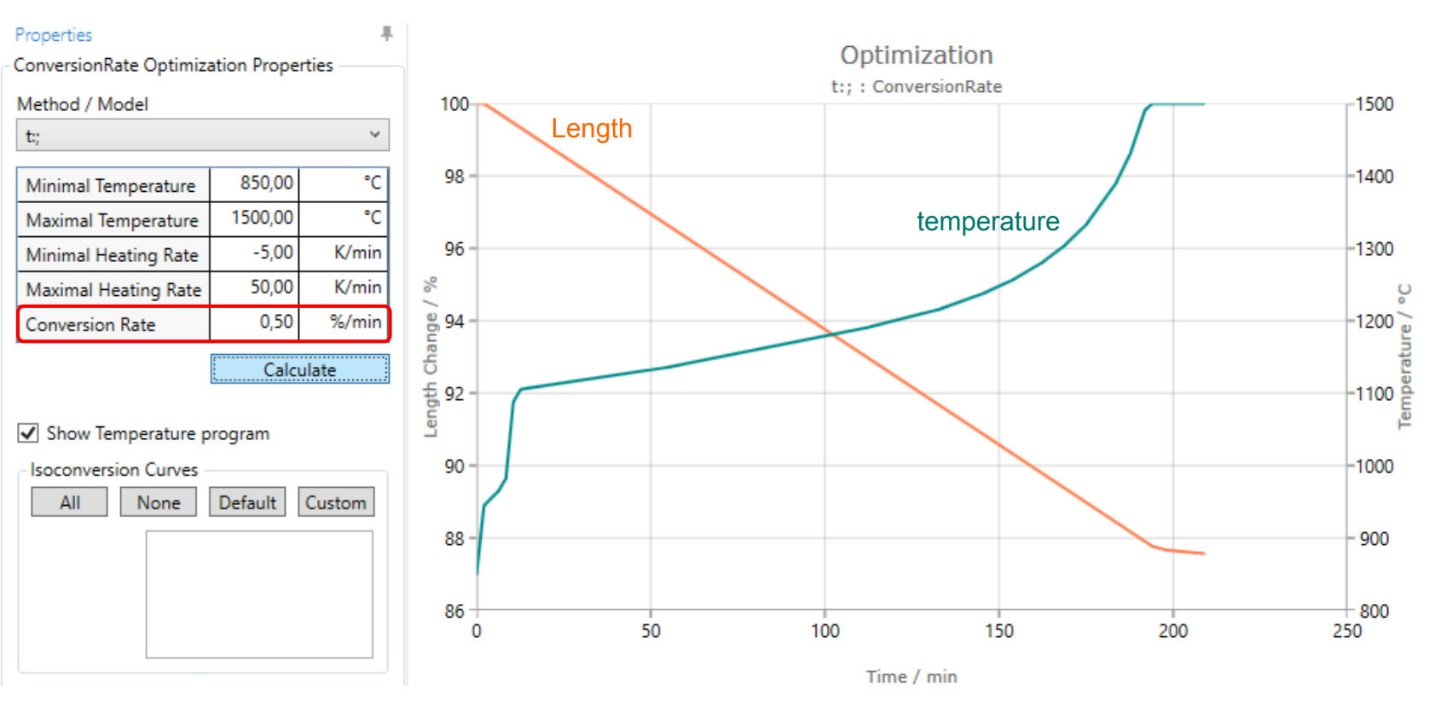

With respect to the conversion rates in every sintering step, you can optimize you firing program directly in the software and see, how the change of program will affect the sintering process and the conversion rates for every step. Too big conversion rates can cause cracks or deformation on your parts. The model for the conversion rates can be seen in the picture based on different heating rates. The challenge is to find out, what the maximum conversion rate will be without compromising the quality. Next to more complex sintering programs, the easiest first step is to simulate with a constant conversion rate - what you get as a result is the temperature curve:

Fig. 4: Modelled temperature curve based on a conversion rate of 0.5%/min

With optimizing your debinding and sintering process with the respect to maximum conversion rates and the ability of your furnace in terms of heating- and cooling rates, you will get close to the optimum with modelling your firing program in the software. With Kinetics Neo Simulation, you will get faster to the optimum!

Real Life Example: Optimization of Ceramic Production in Industry

The German company Haldenwanger produce the wide spectrum of ceramic materials for different purposes. It continuously develops the new ceramic materials with the better physical properties.

The new ceramic material HALOFOAM ALUMINATM has the excellent physical properties, but the final quality of this the ceramic foam is highly sensitive to temperatures rates of firing. The slowing of the heating leads to the perfect quality, but has too long production time and very high production costs.

Therefore, the firing process of this ceramic production requires the optimization of its temperature profile and the heating rates. However, the experimental "trial & error" method does not work here, because each production cycle continues many days in the firing chamber and has high costs.

The optimization of the temperature profile was done in the Kinetics Neo software.

This process contained two parts, debinding and then sintering.

The measurements for debinding with different heating rates were done on STA 449 F1 on NETZSCH laboratory. Then the kinetic model for debinding process was created and the temperatures below 700°C for debinding only were optimizes in Kinetics Neo.

The measurements of shrinkage during sintering were performed on dilatometer in NETZSCH laboratory too. The second kinetic model for sintering and then optimization of the temperatures above 700°C for sintering only were done in Kinetics Neo again.

The total optimization of the temperature profile was carried out for both parts and the production time was reduced by more than 50%.